78-year-old D Suresh lives with his wife, son and daughter-in-law in Kilpauk, and he says he has bought only two LPG cylinders per year since 2012. His family does not eat outside every day, nor do they use electric or induction stoves for cooking their daily meals. “It is not rocket science,” says the septuagenarian when he says that he has been generating his own cooking gas from kitchen waste for over nine years. When the waste decomposes in the absence of oxygen, Suresh gets biogas that he uses for cooking. This process does not happen in a scientific laboratory but in his very own house, in the biogas installation that he has set up.

Apart from generating cooking gas, biogas production also gives rise to a slurry as residue, which can be used as an organic manure for plants.

Suresh has had a rooftop solar panel for years now and often fellow citizens come to him to consult him about rooftop installations. “About 10 years ago, a person came to see my solar set-up. In the course of conversation, he said that he was in the business of biogas and in response to my questions, explained how it was possible to produce cooking gas using kitchen waste at home. That really excited me,” narrates Suresh.

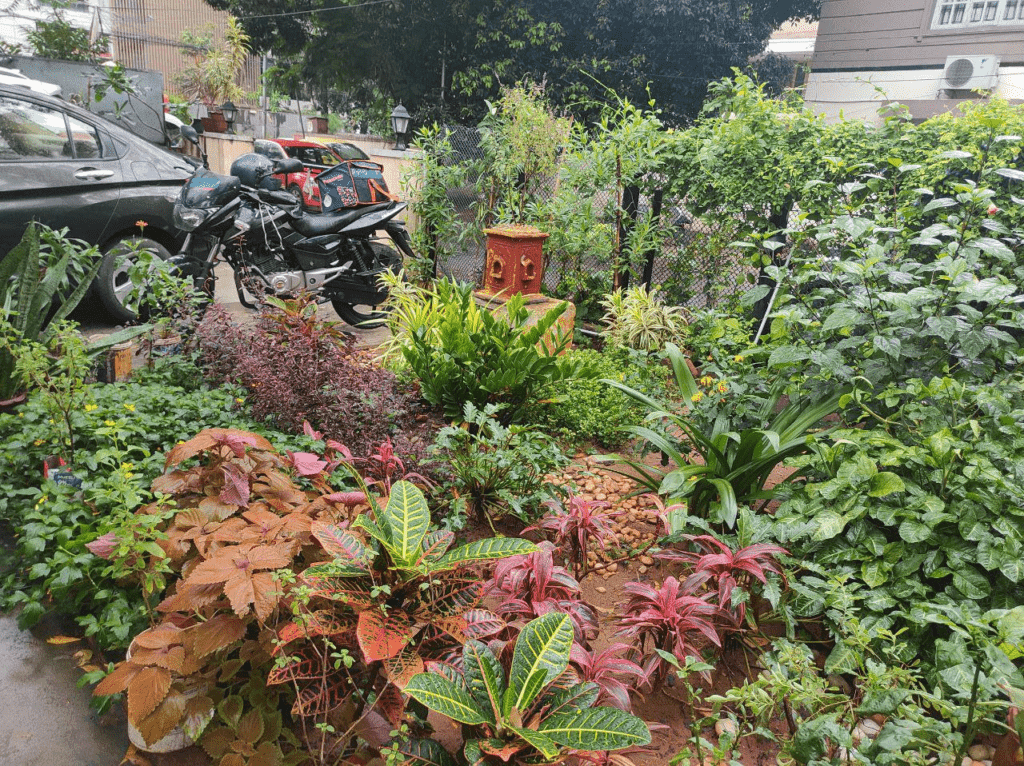

Today, Suresh’s independent house of more than 2,000 square feet sets an example on several fronts — his small front lawn dotted with plants, his terrace bearing the rooftop solar panel, and his backyard boasting a rainwater harvesting system, a well and a biogas plant.

Read more: Solar rooftop for your home in Chennai: Challenges and solutions

Installing a biogas plant: DIY tips

“A biogas plant consists of three components – a digester, a gas storage container, and a burner,” states M Jagadesh, a biogas vendor.

He stores his kitchen waste in a large bucket.

Before feeding the kitchen waste, it is important to process it and convert it into a semi-solid pulp, so that there are no solid bits of waste which may get stuck in the biogas plant, hindering the biogas production, instructs Jagadesh.

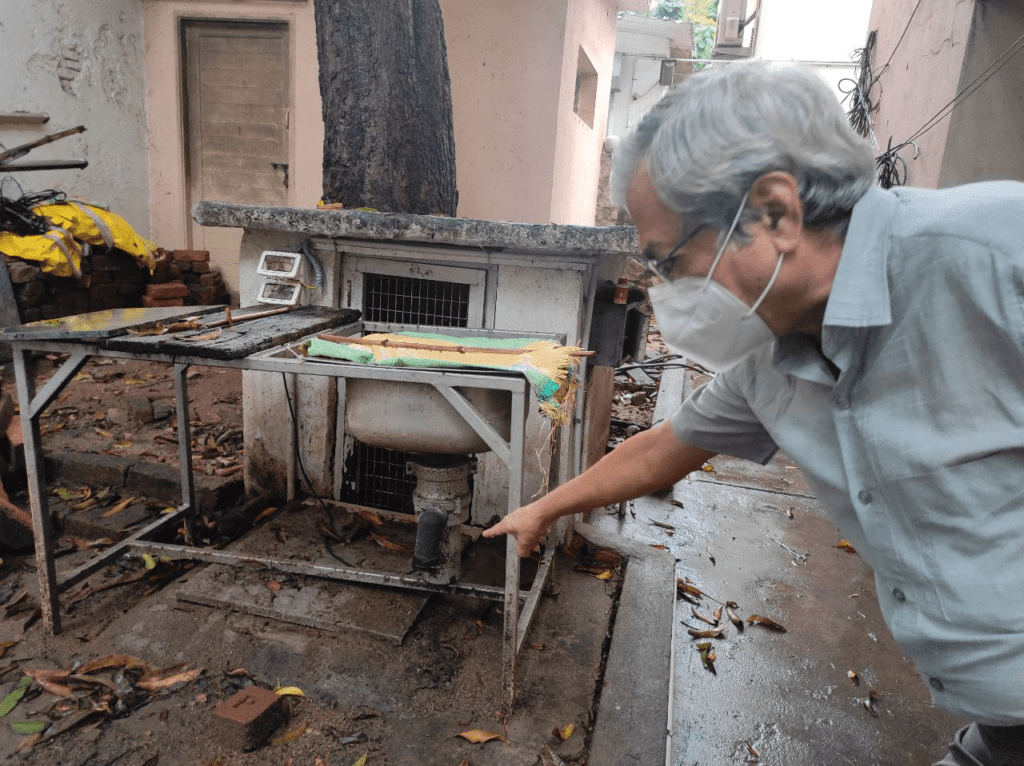

Suresh passes the waste through a sink fitted with a crusher, and waste comes out as pulp. Jagadesh says one can process the waste in a mixie too.

The processed kitchen waste is then fed into the digester, which is essentially a large tank-like structure. This is where the biogas is eventually produced. When one feeds wet waste into the digester, bacteria break the waste down over time to produce biogas, releasing a slurry as a by-product that can be used as organic fertiliser for plants. This process is called anaerobic digestion.

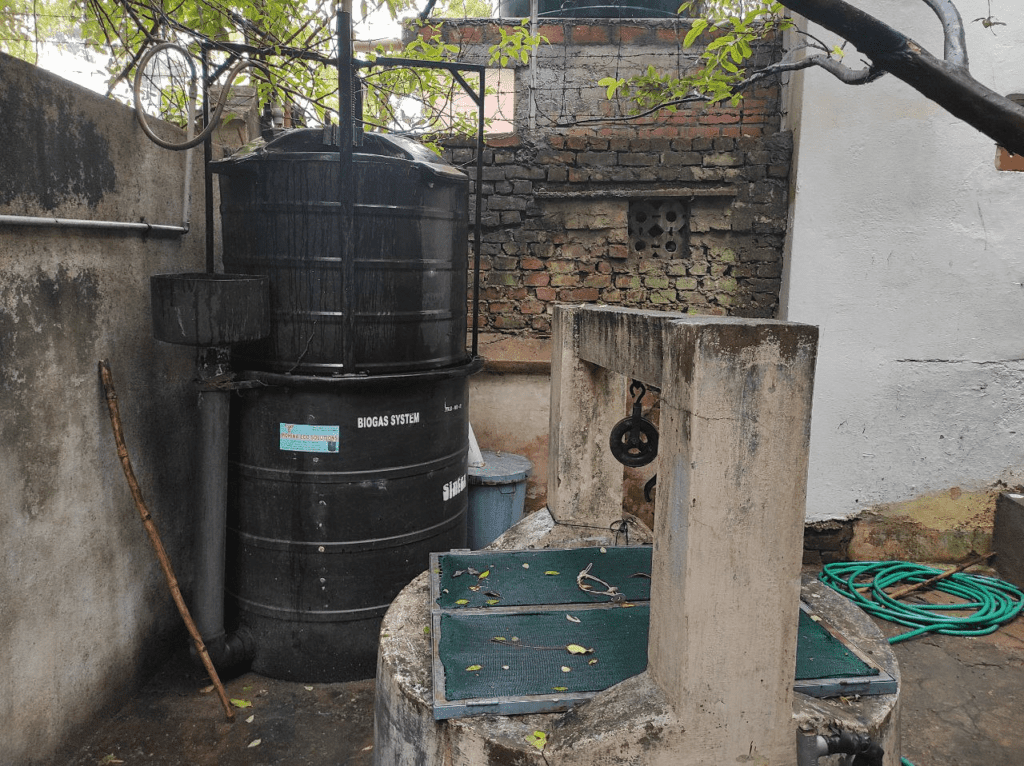

Usually the digester is a modified Syntex tank, says Jagadesh. The tank touching the ground is the digester of Suresh’s biogas plant. He feeds the kitchen waste into a bowl-like structure that is on the left to the tank.

Just above the digester, Suresh has a floating drum, which is the upper tank-like structure that you see in the picture below.

As biogas is produced inside the lower tank, it rises up to fill the gas storage container above, propelling it upwards.

Then as the biogas is gradually consumed, the floating drum is pushed down. When the drum is halfway down, Suresh feeds the next batch of waste into the digester.

Alternatively, the floating drum may be replaced by a bag, as Maria Rosita Jansi from Madambakkam has done for her set-up. The bag is inflated as the digester produces biogas. Maria checks the bag regularly and whenever it is deflated beyond a point, she feeds her next batch of waste to the digester.

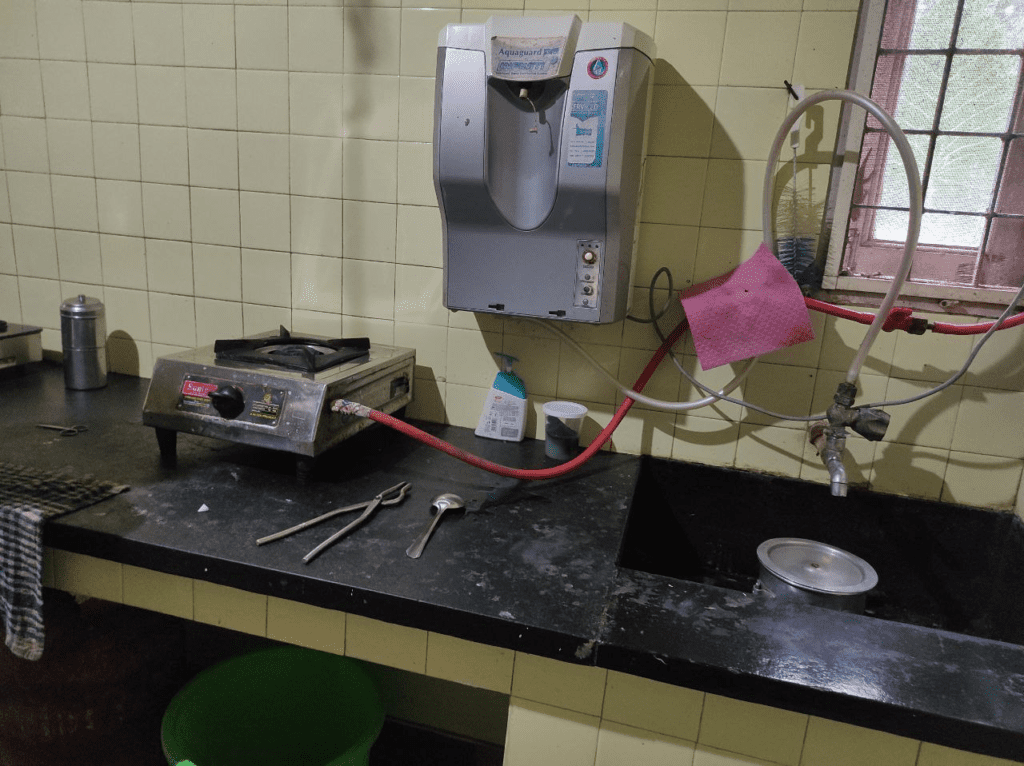

The storage connects to the burner, where one does the cooking, via gas pipes. Pipes connect the floating drum to a burner in Suresh’s kitchen. The pipes run along the walls in his backyard, go through his kitchen window and are attached to his burner.

Suresh says he has spent around Rs. 40,000 to build the entire system.

As the biogas is produced in the digester, slurry is also let out and collected in a separate bucket, as shown in the picture below. Suresh dilutes this with water and adds it as a fertiliser to his plants.

No foul smell is generated when the gas is being produced in the plant. It is a clean and safe process, he affirms.

The nitty-gritty of producing biogas

When Maria installed her biogas plant in her house eight months ago, she fed her 500-litre digestor with cow dung. “In the initial stage, you need to feed the digester some starter material, typically cow dung, as it generates bacteria, which in turn reacts with the food waste to generate biogas,” explains Suresh.

“Biogas is a mixture of methane, carbon dioxide, and hydrogen sulphide. Methane gives the flammable property to biogas to be suitable for cooking,” explains Dr B Samuel Jacob, Assistant Professor of Biotechnology at SRM Institute of Science and Technology.

“We need a specific bacteria, called ‘methanogenic bacteria’ for production of methane gas and it is abundant in the digestive system of cattle, hence available in the dung. Substitute for cattle dung is sewage sludge, which is a residue from the bottom of sewage. But, cattle dung is the best and a safe starter for biogas digester. Recently, ready-made microbial solutions are available in the market that can replace cattle dung,” says Professor Samuel.

Jagadesh also says, “I have heard that there are substitutes (to cow dung) available in the market. But we haven’t practically tested them to check their efficiency. Cow dung is available easily [in the city] and works well.”

However, it is not necessary to feed cow dung every time or even frequently. Suresh has not fed the digester with cow dung since the initial stage of biogas production. “I don’t get cow dung in my area,” he says, while Jansi occasionally does introduce it in her digester, as it is available in her locality.

Professor Samuel explains that feeding cow dung for the first time is necessary, but after the first batch of biogas is produced, kitchen waste would suffice. The methanogenic bacteria (from the first batch of cow dung) will take the nutrients from the kitchen waste and flourish.

For Suresh, it took 10 days for the gas to form after feeding cow dung for the first time, while Maria says it took 15 days the first time for her set-up to yield gas.

What kind of kitchen waste should you feed into the digester?

Suresh feeds kitchen leftovers, cooked food, uncooked food, spoiled food, vegetable peels in the digester. “Even bones and leftover meat can be fed,” informs Jagadesh, but the only catch is that the waste must be in liquid or semi-solid form. Therefore, it is better to either soak the waste or grind it in a mixie before feeding it into the digester. This is because the solid bits of waste may get stuck in the plant, hindering the biogas production.

However, one should avoid feeding the digester with citric foods or raw onion and garlic peels, dry leaves. “These have antimicrobial properties and can negatively affect the [biogas production] process,” says Professor Samuel Jacob.

The important thing is to feed kitchen waste regularly. If waste cannot be fed regularly enough, then some cow dung can be fed. This will again bring the methanogenic bacteria back, helping the biogas production process to resume.

Cow dung can also be added if the flame from the biogas burner is weak while cooking. This indicates a low percentage of methane in the biogas. Methane gives biogas the flammable property. Adding cow dung will boost the methane percentage in biogas, owing to the methanogenic bacteria.

“I feed waste once or twice every week. It just takes about ten to fifteen minutes to get it ready to be fed into the tank,” shares Suresh. He has a 1000-litre digester, in which he feeds waste of about 4-5 kilograms per day.

“I hardly generate 200-300 grams of kitchen waste per day,” confirms Suresh, and he sources the rest of the waste from neighbours and a couple of vegetable shops in his area. He says they are happy to give him their wet waste. He reveals that his biogas plant can produce as much gas as produced by an LPG cylinder per month.

On the other hand, Maria has a smaller set up: a 500-litre digester. She feeds approximately 10 litres of waste (in liquid form) every couple of days. “My husband and I are the only residents of my house, and we don’t need a lot of cooking gas,” she says. This gets her enough biogas to cook for an hour each day.

Read more: Converting kitchen waste to compost: Why are our cities stumbling?

Rewards of opting for biogas at home

Apart from the obvious environmental friendliness of biogas, when compared to LPG, there are several immediate benefits of opting for a set up of the kind described above.

One, as already mentioned above, is the residue that is obtained from biogas production. Maria dilutes the slurry with water and has added new plants in her backyard garden, encouraged by the fertilising properties of the above. Even Suresh says, “I started with 20 pots. Today I got about 150 potted plants in my house (thanks to the use of the residue).”

But there is more to this. “If there is any sewage or stagnant water around your house, working as breeding ground for mosquitoes, you can keep pouring the slurry you get in the sewage water. The bacteria in the slurry can kill the mosquito eggs, thus putting an end to the infestation,” elucidates Jagadesh.

Biogas can also be used to generate electricity, shares Professor Samuel.

Challenges of generating and using biogas

- It is not as efficient as LPG for cooking, says Dr. Samuel, adding that when the percentage of carbon dioxide, which does not support burning, is high, the efficiency of biogas reduces. If the methanogenic bacteria is less, the percentage of methane will be less and carbon dioxide will be more, explains the professor. At this point, one can add more cow dung to make up for the gap.

- To set up a biogas plant, space is needed. Jagadesh says that an area of at least 3 feet diameter is required to set up a 500-litre biogas digester. A gas bag can be hung on the wall so that the space required can be reduced to some extent. Maria, for example, has hung her biogas bag on a wall in her house.

- Generating an amount of food waste enough to produce significant quantities of biogas is difficult. “Biogas must be looked at as a waste management method, and not as a substitute for LPG,” remarks Suresh.

- More efforts are needed to keep the biogas plant active and running, compared to the efforts required to maintain an LPG connection, says Dr. Samuel.

- Biogas cannot be used to run two burners, as it has lower pressure. One can only use one burner for cooking with biogas.

The feasibility of biogas installation in apartments

Suresh says that apartment complexes may not always have the luxury of space to set up a biogas plant. He says that it may need 400 to 500 square feet of area to install a large biogas plant.

However, he is hopeful that individual houses in an apartment can take the initiative to install biogas plants if they have space. As per Jagadesh’s estimate above, if the family opts for a 500-litre biogas plant (the minimum range), a space of around 3 ft diameter would be enough.

The other challenge is that even if there is a common large biogas system in an apartment complex, it would be hard to distribute the gas to individual houses because the biogas produced will have low pressure.

Even if apartment complexes optimise the system to produce more flammable gas and ensure high pressure through use of a compressor, Jagadesh believes that the amount of waste generated collectively would not be enough to produce enough cooking gas for all units. “The amount of gas obtained by each family would only be enough to probably make a cup of tea with it, if the biogas generated is distributed equally to all the houses in an apartment,” he says.

The bottomline, therefore, is that it would simply not make economic sense to have one big plant at the apartment level.

Recommendations to optimise the biogas production

Dr Samuel suggests some tweaks that can be made in the biogas plants to enhance the quality of biogas that is used for cooking.

- A compressor may be used in between the gas production area and the usage area (burner), as the pressure is less. Pressure will increase its flaming property.

- He also suggests that the biogas can be run through a water stream, where the carbon dioxide can be dissolved, purifying the methane in the gas, making it more efficient for cooking.

The bigger picture

“We are all segregating wet waste and dry waste before disposal. But we do not know where and how they are used. They may even all end up in a landfill,” says Suresh. When organic matter decomposes in landfills, it produces methane, and it is one of the most potent greenhouse gases responsible for global warming. As Professor Samuel says, channeling the methane to a useful purpose by recycling kitchen waste is a much more sustainable approach.

Jagadesh emphasises the monetary value of waste and points out that people tend to view wealth in terms of money only. For example, in their mind, they always attach greater value to Rs 40 than a plate of idlis, which may cost the same. “Why don’t you do an audit of all the kitchen waste you generate and assign a monetary value to it? You will see how much money you are throwing away as leftover food and other wet waste.”

The Greater Chennai Corporation and the Tamil Nadu government have set up some biogas plants across the city, but that is not enough, says Suresh. He quotes former American President, John F Kennedy while asking people to take up the reins themselves and install biogas plants in their homes: “Ask not what the country can do for you. Ask what you can do for the country.”

Some vendors who help with set-up of residential biogas units in Chennai

1. M Jagadesh

Tamil Nadu Biogas

Phone: 81248 20036

Price: Starting from Rs. 19,950 excluding tax, for a 500-litre biogas plant

2. Banupriya Krishnaprabhu

Managing Director of Sewaf Energy Private Limited

Phone: 86758 17158

Price: Starting from Rs. 20,000, for a 500-litre biogas plant

We had this setup in our village like 25 year ago. Bottom chamber was built under ground and 5 feet diameter drum was used on top. Mainly using cow dung. Gas would support cooking for about 35 people daily three times.

Portable solutions are great for independent house.

Hello, how to do cant understand exactly.

Its very good and eco friendly system

Dear Padmaja

I would love to cover one of the bio gas set up in my YouTube Channel “Interior Dost”.

Can you please share the details of family who are using bio gas.